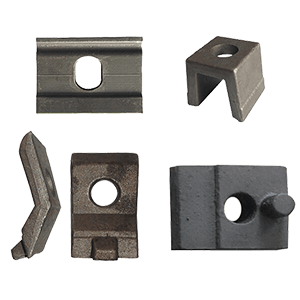

Tie plate

The tie plate, which also can be called as base plate or sole plate, is made of either mild steel, cast iron, wrought iron, or malleable steel, it’s interposed between the foot of a flat footed rail and wooden sleeper to distribute the load on a larger area. The tie plate is fastened to wooden ties by means of spikes or bolts through holes in the plate. The part of the plate under the rail base is tapered, setting the cant of the rail, an inward rotation from the vertical. The top surface of the plate has one or two shoulders that fit against the edges of the base of the rail.

Types of tie plate:

1. The tie plate can be either casting iron or casting steel, depending on the load and the type of rails. Cast iron can be the welded or fabricated type, depending on the customers’ requirements.

2. The double-shoulder type is currently used. Older single-shoulder types were adaptable for various rail widths, with the single shoulder positioned on the outside (field side) of the rails.

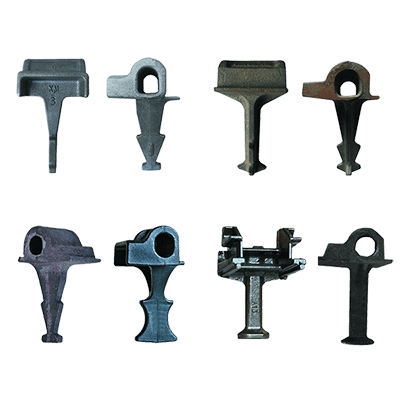

Main Functions:

1. Railroad plate is used in rail construction to support the rails, and also to take the load of rail and distribute the load to the sleepers;

2. The railroad plate increases bearing area and holds the rail to correct gauge;

3. The railroad plate prevents damage of the sleepers due to rubbing action and holds the spike firmly to the sleepers.