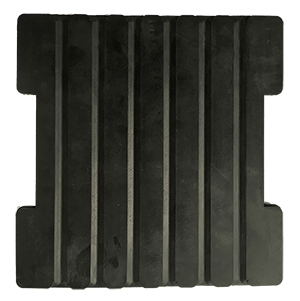

Rail Pad

Rail Pad, which is assembled under the steel rail, it’s main functions is Loading distribution over a larger surface & Elimination of load concentration and the resultant fatigue stresses & Centering of loads on the supporting element & Absorption of uneven contact surfaces between rail and support & Reduction of noise and vibration & Sealing between the bottom of the rail and the top of the support Reduction of wear of the rail and its support.

Rubber Pad

Stiffness: 90-130KN

Tensile Strength before Aging : ≥ 12.5Mpa

Elongation before Aging: ≥250%

Melting Point: 72-80 ℃

Electronic Resistance: ≥ 106 Ω

EVA Rail Pad

Density: 0.95-0.98 g/m³

Tensile Strength: ≥ 15Mpa

Elongation: ≤500%

Melting Point: 170 – 190 ℃

Insulation Resistance: ≥10,000,000 KΩ

Hardness: ≥90A

HDPE Rail Pad

Density: 0.95-0.98 g/m³.

Tensile Strength: ≥19Mpa.

Elongation: ≥80%.

Melting Point: 170-190 ℃

Insulation Resistance: ≥10,000,000 KΩ

Hardness: ≥98A