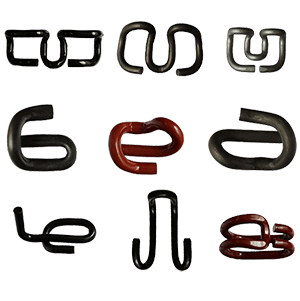

Rail Dowel

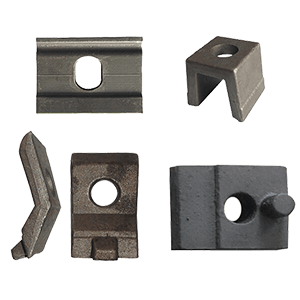

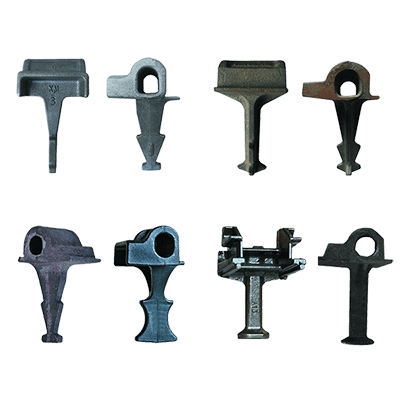

Rail Plastic dowel, Rail socket, or Rail sleeve is pressed in concrete sleeper and assembled with sleeper screws, guide plates and rail clip to fix the rail. The material can be either HDPE or PA66 , which is depend on the technical requirements. The color is available in white, black and dark brown.

It is used to guarantee the good connection and linkage of the rail fastening system with the concrete sleeper, together with screw spikes or bolts. The collaboration of screw spikes or bolts and embedded plastic sleeves makes the guide plate or tie plates be tightly fastened to rail and sleeper, through rail clips, to fulfill a enough elasticity range, and also to prevent the spike from loosening. Therefore, the quality of this small pre-inserted part into the concrete sleeper, especially its strength and fatigue life, is of great importance to the whole rail line.

HDPE Rail Dowels

Density: 0.95-0.98 g/m³.

Tensile Strength: ≥19Mpa.

Elongation: ≥80%.

Melting Point: 170-190 ℃

Insulation Resistance: ≥10,000,000 KΩ

Hardness: ≥98A

PA66 Rail Dowels

Density: 1.3-1.45 g/m³

Tensile Strength: ≥ ≥170Mpa

Elongation: ≤4.4%

Bending Strength: ≥250Mpa

Impact Strength (No gap): ≥80 KJ/m2

Melting Point: 250 – 270 ℃

Insulation Resistance: ≥100,000 KΩ

Hardness: ≥110A

Glass Fiber Content: 30-35%